China High Quality Copper To Brass Fitting Suppliers – Forging hexagon hose nipple elbow Brass fitting plumbing brass Tee Pipe Connector forged brass press male coupling – Fengcai

China High Quality Copper To Brass Fitting Suppliers – Forging hexagon hose nipple elbow Brass fitting plumbing brass Tee Pipe Connector forged brass press male coupling – Fengcai Detail:

Product Details

Lead Time:

| Quantity(Sets) | 10000 - 50000 | >50000 |

| Est. Time(days) | 60 | To be negotiated |

Customization:

Customized logo(Min. Order: 10000 Pieces)

Customized packaging(Min. Order: 10000 Pieces)

Graphic customization(Min. Order: 10000 Pieces)

Measures for quality inspection of plumbing fittings

With the development of market economy, some fake and shoddy plumbing spare parts are falling into the sand, seriously threatening the quality of plumbing engineering, affecting the normal life of thousands of families.

Inspection and identification

1. Visual inspection: visual inspection of accessories. Visual inspection is very important, such as radiator, see its rough appearance, sand is not good and serious wing is inferior quality; Poor electroplating of galvanized pipe fittings for water supply, poor surface and improper thread are inferior products.

2. Blowing test: it is to use the mouth blowing method to check. Such as manual exhaust valve, needle valve, water nozzle, small ball valve, etc., can close the valve, and then blow with the mouth, blowing to the valve side check whether the valve leakage, such as leakage, prove that the valve is not strict, can not be directly installed. The elbow, tee and other parts with pits or suspected sand holes can also be identified by blowing before installation.

3. Disassembly: is to disassemble the parts for inspection, such as a live joint, can be disassembled to see whether the male mouth butt and the female mouth mouth is buckled, is not oblique butt, or not on, not bite; Take a look at the female internal thread and female mouth external thread bite is tight? How much is the effective deduction? How tight is it? These can be identified by dismantling. In addition, the collecting tank can also be dismantled for inspection to see whether the floating ball valve is out of order and whether there is an exhaust hole.

RFQ

Q1:Does the company accept the mold fee? How much is? Can I refund it? How to refund it?

A:We need receive mold fee when we open new mold.This fee is depends on products. Reach a certain amount, you can refund the mold cost.

Q2.What is your production process?

A:For custom made copper fittings.

1.First, we need sample or detailed drawing,and we offer price for customer. 2.Then,we give reasonable mold fee, and need approval to open new mold. 3.Last, negotiate price—give 30% payment…set contract…

Product detail pictures:

Related Product Guide:

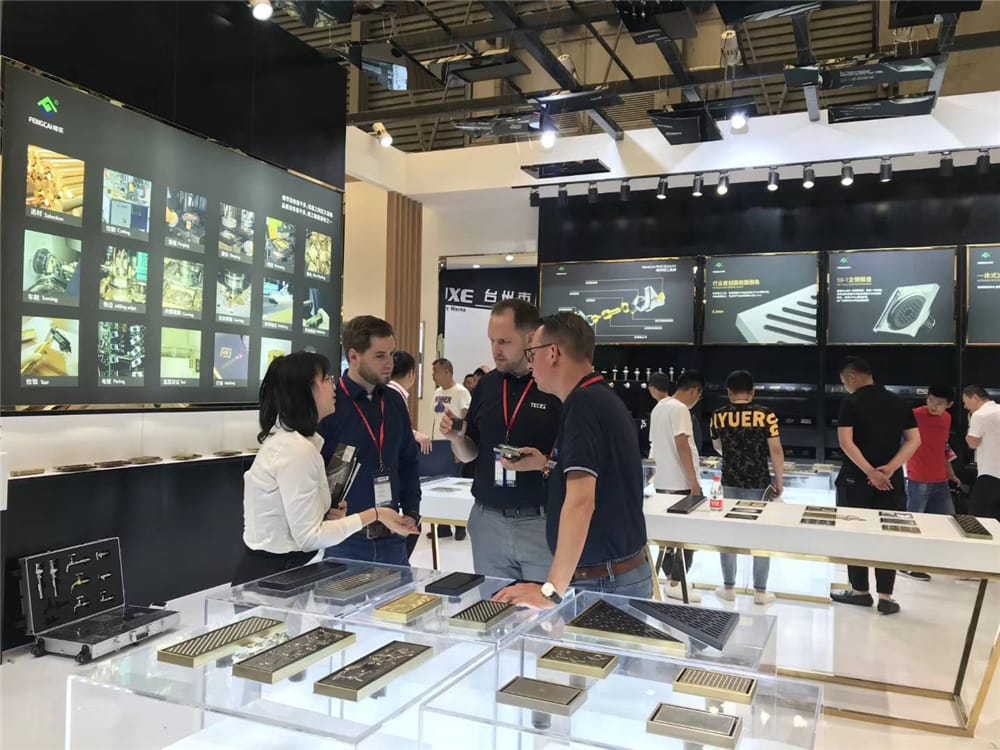

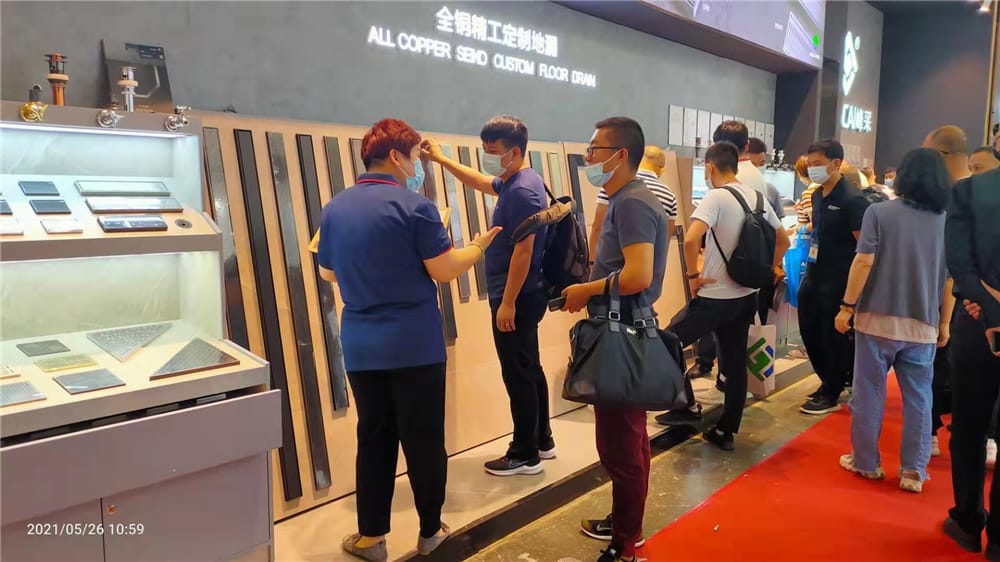

We have our own product sales staff, style crew, technical group, QC staff and package staff. We now have strict high quality management procedures for each approach. Also, all of our workers are experienced in printing subject for China High Quality Copper To Brass Fitting Suppliers – Forging hexagon hose nipple elbow Brass fitting plumbing brass Tee Pipe Connector forged brass press male coupling – Fengcai , The product will supply to all over the world, such as: Sao Paulo, Toronto, Casablanca, With more and more Chinese products and solutions around the world, our international business is developing rapidly and economic indicators big increase year by year. We have enough confidence to supply you both better solutions and service, because we've been more and more powerful, specialist and experience in domestic and international.

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme", we have always maintained business cooperation. Work with you,we feel easy!