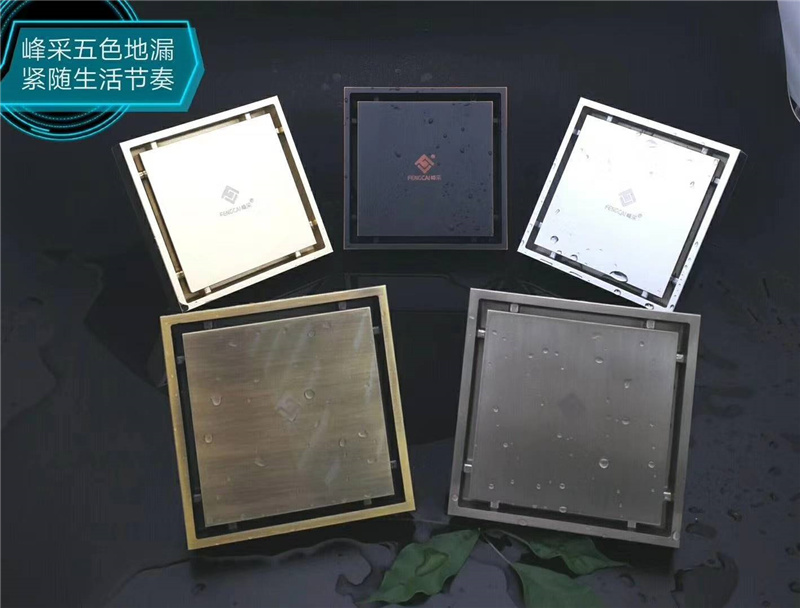

Brass concealed floor drain Square Shower brass Floor Drain with Tile Insert brass square tile insert floor drain Invisible Tile Insert brass Floor Drain

Video

Product specifications

| Item number | Weight | Color | package | Size

|

Picture |

| DL10-10YX

(Brass material) |

670g | Chrome

Bronze Nickel Golden Black Gun gray |

Brown box/

Color box; 48pcs/ctn |

10cm*10cm |  |

| DL10-10YX-Y

(Brass material) |

414g | Chrome

Bronze Black Nickel |

Brown box/

Color box; 48pcs/ctn |

10cm*10cm |  |

Detailed picture

DL10-10YX

DL10-10YX-Y

How to make a high quality floor drain?

On the process of Forging

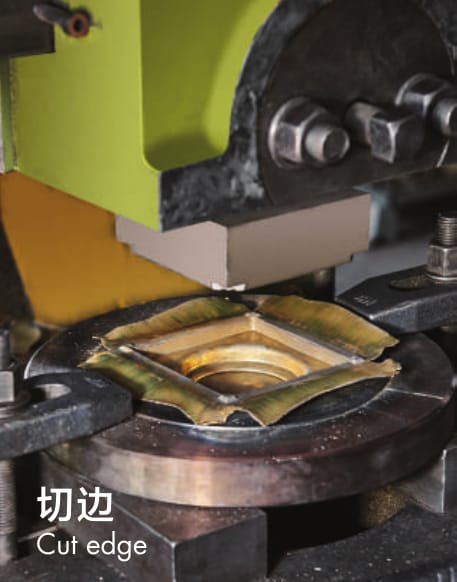

On the process of cutting edge

semi-finished product

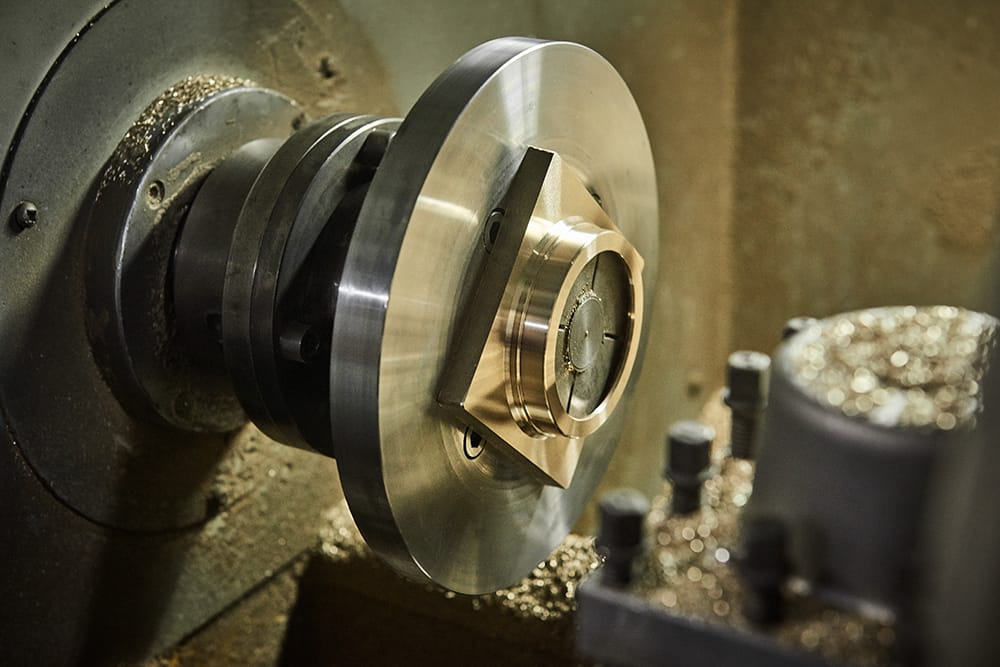

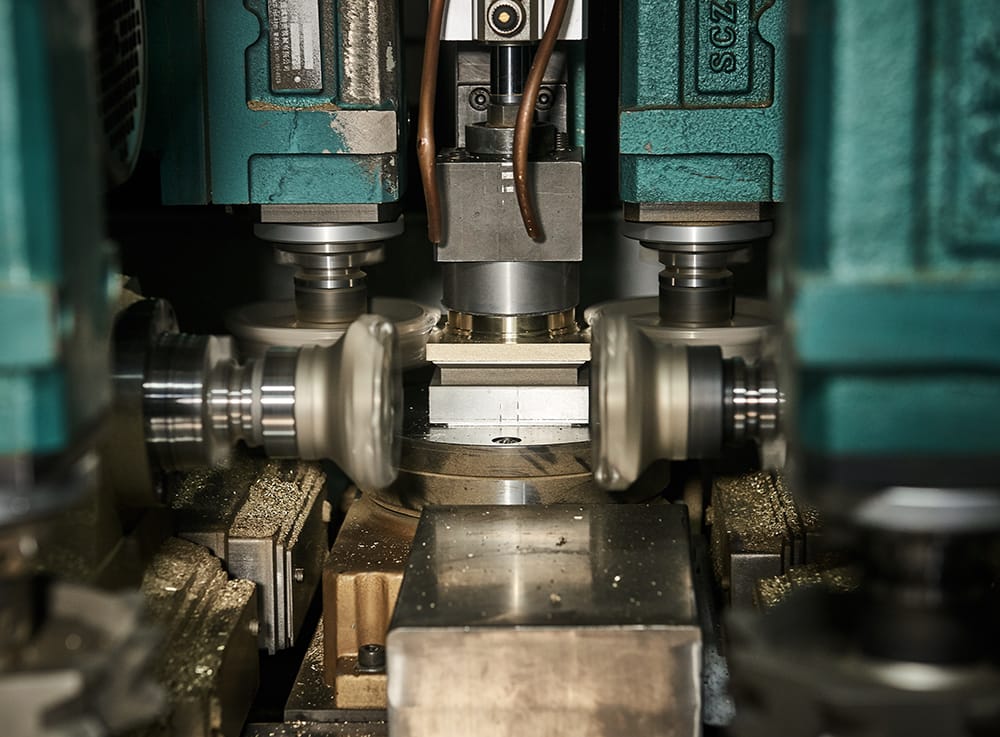

On the process of Turning,milling edge

On the process of inner wall carved,polishing and Test

RFQ

Q1: How do you do about quality control?

A: Quality is above everything. We always attach great importance to quality controlling from the beginning to the end. Each products are tested one by one which must be in accordance with the factory quality standard before arranged to packing.

Q2:What is your production process?

A:There are 17 processes to complete a floor drain:

1. selection of raw materials

2. cutting materials

3. Forging

4. shaping

5. cut edge

6. shot blasting

7. turning

8. milling edge

9. inner wall carved

10. pattern carved

11. Polishing

12. fine polishing

13. Electroplating

14. inspection

15. salt spray test

16. print logo

17. packaging

Q3:How to select good floor drain?

A: The special features of floor drain: it excludes surface water, water stains, solid things, fiber things, hair, easy to deposit, etc .Floor drain should have four characteristics: fast drainage, odor prevention, blockage prevention, easy to clean.