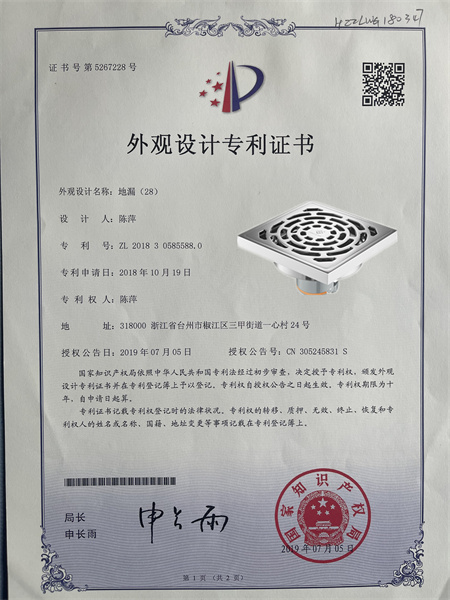

10cm brass floor drain Silicone Hair Catcher for brass floor drain Metal Shower Trap Polished Brass Shower Drain patent product

Products information

Item number:DL10-10FJ-12

Material :GB-hpb59-1 brass

Package: brown box/color box per piece

Size:10cm*10cm

Weight:496g

Delivery time: approximate 30 days

Export port: Ningbo ,Shanghai

Sample : support

Application: for bathroom,for kitchen

This product is our patent brass floor drain

| Quantity(Pieces) | 1 – 1000 | >1000 |

| Est. Time(days) | 30 | To be negotiated |

Customization

Customized logo(Min. Order: 500 Pieces)

Customized packaging(Min. Order: 1000 Pieces)

Graphic customization(Min. Order: 5000Pieces)

Significance of using copper fittings

1.In copper water pipe, the advantages of metal pipe such as high strength, rigid, sanitary appliances such as faucets are easy to fix, there will be no faucets installed in non-metallic pipe such as plastic pipe rocking easy leakage.

2.Copper fittings are made of pure copper with copper content of 99.99%. Therefore, copper accessories will not penetrate, corrosion resistance, is conducive to human health. Copper fittings have a service life of more than 100 years, after the actual test

At home and abroad, through the practice of 100 years, cupreous conduit behaved service life is long, safe sanitation, installation is convenient, fire-resistant and corrosion-resistant, did not pollute to the environment, the numerous advantage such as renewable character is good.

RFQ

Q1:Can you identify your own products?

A: Sure,the products look the same,we also can identify it.

1) Weight is different,we have precise weight for each mould.

2) Quality: we will check polishing and plating state

3) Forging technique.

4) Every floor drain core we have patent letter on it

Q2:What are the components of your product? What are they made of?

A:For floor drain,we have 5 components : cover;main body;core;seal circle,hook

Cove and main body are made of brass;Core and seal circle are made of ABS;Hook is made of stainless steel.

Q3:What is your production process?

A:There are 17 processes to complete a floor drain:

1.selection of raw materials

2.cutting materials

3.Forging

4.shaping

5.cut edge

6.shot blasting

7.turning

8.milling edge

9.inner wall carved

10.pattern carved

11.Polishing

12.fine polishing

13.Electroplating

14.inspection

15.salt spray test

16.print logo

17.Packaging